The production supply chain

We have been buying our cocoa beans straight from São Tomé, Peru and Nicaragua and we subsequently process them in Belgium into chocolate bars. This is a huge change if you consider that 90% of the chocolate bar market consists of couverture chocolate (chocolate that is bought from large producers and is poured into a form by the manufacturers).

But what difference does the relationship with producers make in relation to our approach?

We are in direct contact with the producers. This means that we can guarantee a fair price and better working conditions.

“The previous agents could only give us evasive answers to our questions. We then arrived at the idea to buy cocoa beans directly from producers to ensure our traceability was more transparent.

In total, we work with forty producing families that receive a fixed price from us all year round so that their families are protected from speculation by the large cocoa traders.

On the other hand, we decided to pay our producers more than the standards applied in the region for fair trade.

An appropriate payment of producers gives them stability, but also the option to send more than the eldest son to school, etc. It also has a motivating effect on local youth.

How is Nao chocolate made?

1. Harvesting

First, the cocoa pods are harvested, which usually takes place twice a year. This is a manual process where the pods are immediately cut and the pulp is removed so that it can start to ferment.

2. Fermentation

The pulp (from the beans) is left to ferment for a duration of five to seven days. This means that there can be an infinite variety of different tastes depending on the area, process and duration of the fermentation.

3. Drying

Next, the beans need to dry completely spread out in one single layer in the sun.

4. Roasting

There is not one secret recipe and every chocolatier has his or her own temperature and roasting time, which is another step that makes a difference in relation to taste and aroma.

5. Winnowing

Next, winnowing takes place. The beans are cracked and the thin outer layer is blown off. Only the core is later used in the process.

6. Grinding

The heaviest parts that remain (the cocoa nibs) are ground into a paste (called a cocoa mass or chocolate liquor).

7. Conching

Next, conching follows. A very long process where the temperature of the chocolate is increased and decreased several times while being mixed. This is also a very important step to ensure that the final texture is exactly how we want it. The conching machine also maintains a constant temperature so that the pouring phase that follows runs a lot more smoothly.

8. Pouring

The chocolate is poured into a form and cooled down; now we can finally enjoy our bar!

Our production supply chains

Our supply chain in Sao Tomé

In Sao Tomé, we work in collaboration with CECAQ (Cooperativa de Exportação de Cacau de Qualidade)

A cooperative of 20 communities harvesting and exporting cocoa beans.

Each community manages a plot of 1 or 2 hectares. There are currently almost 1,000 people (1,056 to be exact, including 405 women) working for the cooperative, 32 of whom are involved in monitoring, quality control and training.

Our supply chain in Peru

Norandino Cooperative works with small-scale farming communities in the Amazonas department of northern Peru, wedged between the Andes and the Amazon plain. Farmers are located along the Maranon and Utcubamba rivers in the provinces of Bagua and Utcumbamba.

Thanks to investment in cocoa, good farming and post-harvest practices, premium cocoa from the Amazonas department is finding its way to chocolatiers around the world.

Recently, Amazonas cocoa was awarded Appellation d’Origine status.

Sustainable chocolate…

The communities in the Amazon department are fairly isolated from urban areas, and traditionally grow their cocoa using agroforestry methods. The cooperative enables these communities to earn an income while protecting the forests and conserving local biodiversity.

Amazonas cocoa from Peru is produced and certified organically, without pesticides or chemical fertilizers.

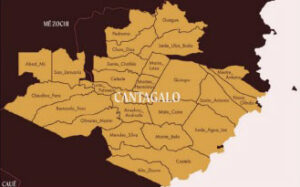

Our supply chain in Nicaragua

In Nicaragua, we work in partnership with the Flor de Pancasan cooperative, awarded the 2019 “Cocoa of excellence” prize for producing some of the world’s 50 finest cocoa. Farmers come here to deposit the product of their harvest, which is then fermented and dried with rigor and attention to detail. This SJM San Pedro (Trinitario) cocoa is grown in the Matiguas region, in the center of the country.